Common Types of Containers

Common Types of Shipping Containers and When to Use Them

Shipping containers are not one size fits all.

Choosing the wrong container can lead to damaged cargo, higher handling costs, delivery delays, or compliance issues once the container arrives in Australia.

This guide explains the most common types of shipping containers used in Australia, what they are designed for, and when each one makes sense in real-world transport conditions.

Why Container Type Matters More Than You Think

Container choice directly affects how freight is handled, transported, and delivered.

From an operational perspective, the container selected impacts loading methods, equipment requirements, delivery access, compliance obligations, and total transport cost.

Mistakes usually appear after arrival, when changes are expensive and time-sensitive.

Dry Containers (Standard Containers)

Dry containers are the most widely used container type worldwide. They are fully enclosed, weatherproof steel containers designed for general cargo.

Common sizes include 20ft containers, typically used for heavier cargo with lower volume, and 40ft containers, commonly used for lighter, higher-volume freight.

They are suitable for palletised goods, machinery, spare parts, and general retail or wholesale cargo.

Weight distribution is critical. Poorly loaded containers can cause axle issues during transport and delays at terminals.

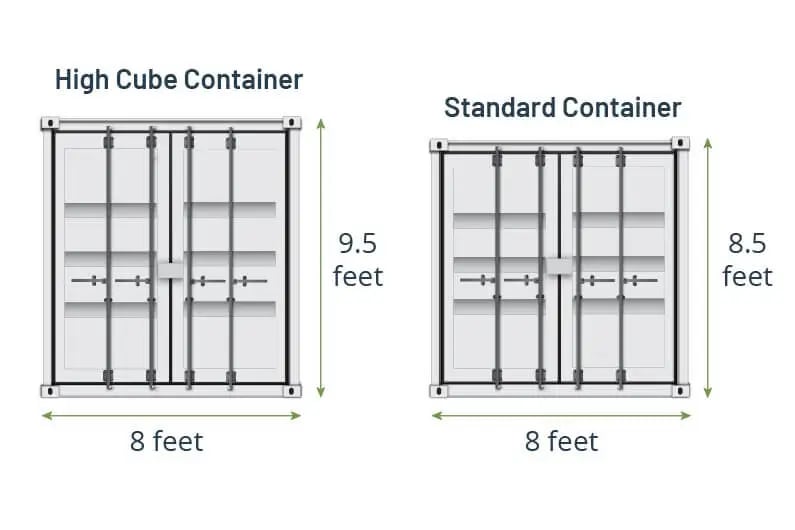

High Cube Containers

High cube containers provide additional internal height compared to standard dry containers.

They are approximately 300mm taller and are commonly used for bulky or lightweight goods that benefit from extra vertical space.

Typical uses include furniture, household goods, oversized cartons, and e-commerce freight.

The additional height can impact delivery site access, particularly in metropolitan areas with height restrictions.

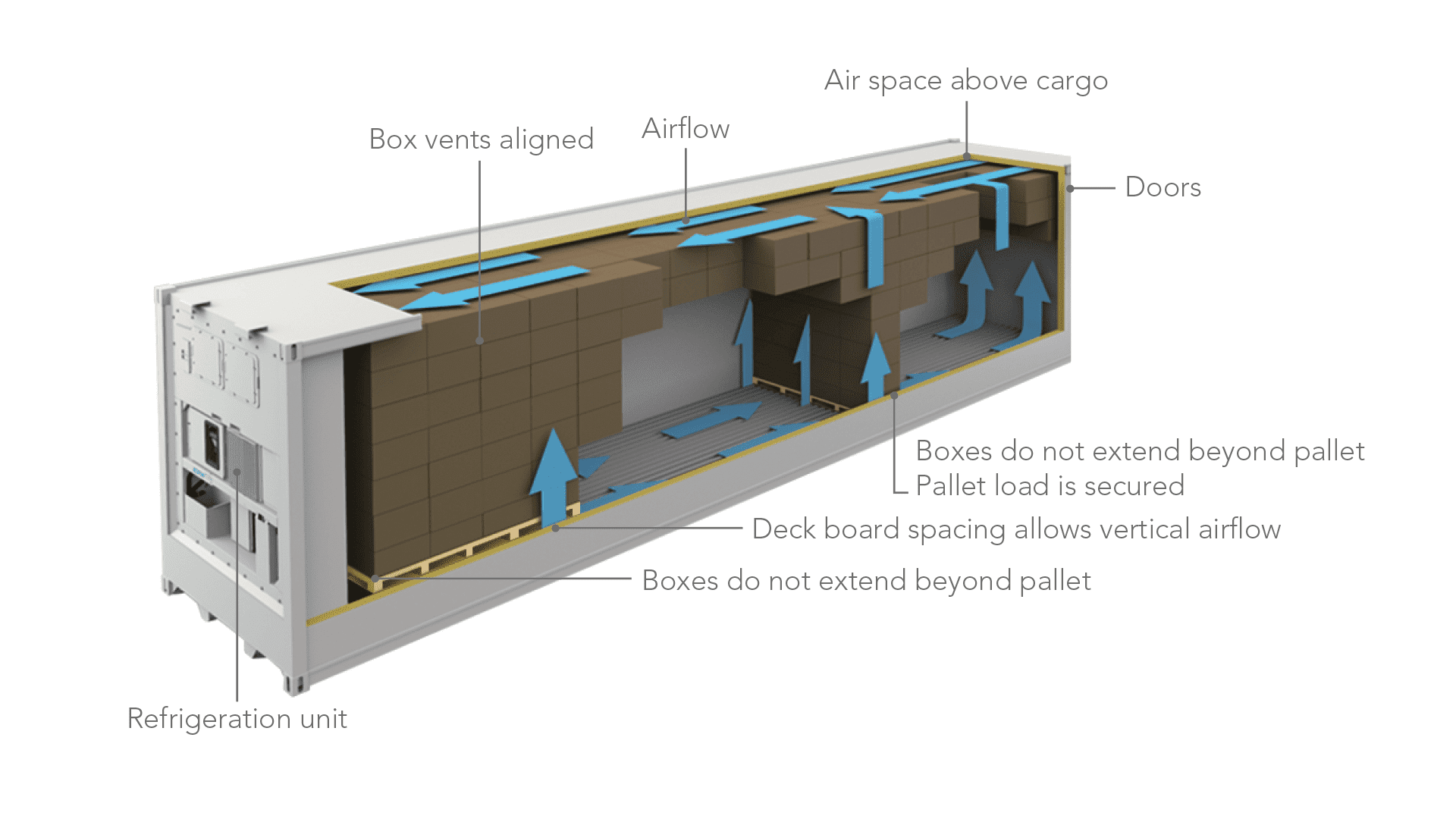

Reefer Containers (Refrigerated Containers)

Reefer containers maintain controlled temperatures throughout transport.

They are commonly used for food, beverages, pharmaceuticals, chemicals, and other temperature-sensitive goods.

Beyond temperature control, reefers require power access at terminals, continuous monitoring, and compliance with cold chain requirements. They also carry higher handling and transport costs.

Open Top Containers

Open top containers are designed for cargo that cannot be loaded through standard container doors.

They are commonly used for over-height machinery, industrial equipment, and construction materials.

Cargo must be securely fastened and properly protected from weather exposure. Inadequate tarping is a frequent cause of cargo damage claims.

Flat Rack Containers

Flat rack containers have collapsible sides or no sides, allowing for oversized or irregular cargo.

They are used for heavy machinery, vehicles, industrial components, and project cargo.

Flat racks often require special permits, route planning, and additional handling equipment. They should always be treated as non-standard freight.

Tank Containers

Tank containers are specialised containers designed for transporting liquids, gases, or powders in bulk.

They are commonly used for chemicals, food-grade liquids, and industrial materials.

Strict regulatory and safety compliance applies. Incorrect handling can create serious legal and operational risk.

Choosing the Right Container Is an Operational Decision

Selecting a container should not be based solely on shipping rates.

The right choice depends on cargo characteristics, handling requirements, delivery access, compliance obligations, and total landed cost.

Operational experience plays a critical role in making the correct decision.

Final Thought

Understanding container types is not just a shipping detail. It is a cost, risk, and efficiency decision that affects the entire supply chain.

Core Logistics approaches container transport with a focus on correct equipment selection, safe handling, clear communication, and reliable execution across Melbourne and surrounding regions.

When containers are moved correctly, everything downstream runs smoother.